The Importance Of The Combustion Chamber In Engine Performance

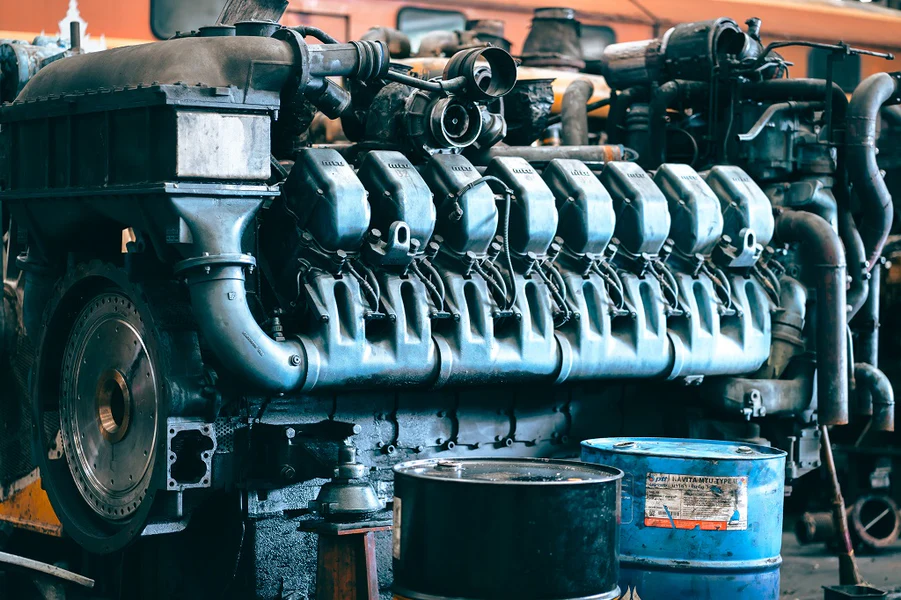

The Anatomy of a Combustion Chamber: What Makes It Tick?

The Design Elements: Shapes, Sizes, and Their Impact

The combustion chamber is a core component of internal combustion engines, pivotal to their operation and performance. At its essence, the combustion chamber is where air and fuel mix, ignite, and explode, generating power that transforms potential energy into kinetic energy. The design of this chamber significantly affects not only the efficiency of combustion but also engine performance. Various shapes, such as hemispherical, wedge, and pentroof configurations, contribute distinctly to the effectiveness of engine operation. For instance, hemispherical chambers allow for better fuel-air mixing and promote a more uniform combustion process, which enhances performance and efficiency. The size of the combustion chamber, in conjunction with its geometry, directly influences the compression ratio and the ability of the engine to maintain a consistent pressure throughout the combustion cycle. A smaller combustion chamber generally supports higher compression ratios, which enables a more powerful explosion; however, it can also increase the risk of knocking if not engineered properly. Ultimately, the interplay among design elements — including the shape and size of the combustion chamber — is crucial for optimizing engine performance metrics like horsepower, torque, and fuel efficiency.

Materials Matter: From Cast Iron to High-Tech Composites

The choice of materials used in constructing a combustion chamber is equally critical, as it impacts heat resistance, weight, and durability. Traditional combustion chambers were predominantly crafted from cast iron, celebrated for its robustness and thermal conductivity. However, advancements in material science have ushered in an era of high-tech composites and alloys that substantially enhance engine performance. For instance, aluminum alloys are increasingly employed for their lightweight properties, which reduce overall engine weight while still providing adequate thermal stability under high temperatures. Additionally, modern composite materials exhibit remarkable resistance to corrosion and thermal fatigue, making them ideal for applications requiring prolonged exposure to harsh conditions. As the automotive industry increasingly focuses on reducing emissions and improving fuel efficiency, new materials not only offer performance advantages but also create opportunities for innovative designs that were previously unattainable. Consequently, understanding the various materials’ properties and their implications for the combustion chamber can lead to the development of engines capable of delivering exceptional performance while adhering to stringent emission regulations.

Understanding the Dynamics: Air-Fuel Mixture and its Role

The dynamics of the air-fuel mixture play a significant role in the combustion process within the combustion chamber. The precise ratio of air to fuel is critical; too much fuel can lead to incomplete combustion and increased emissions, while too much air can cause the engine to run lean, leading to higher temperatures and potential damage. Typically, the ideal stoichiometric mixture for gasoline engines is approximately 14.7 parts air to one part fuel. This ratio enables complete combustion, maximizing the energy extracted from the fuel and minimizing harmful byproducts. Advanced engine management systems utilize sensors to monitor the air-fuel mixture in real-time, providing feedback that allows for dynamic adjustments during engine operation. Understanding these dynamics is paramount for optimizing performance; in practice, many performance-oriented engines utilize techniques such as turbocharging or supercharging to enhance air intake, thus allowing for a richer air-fuel mixture without sacrificing efficiency. Preparing an optimal air-fuel mixture not only influences raw power output but also contributes to the smooth operation and longevity of the engine, making this a vital aspect for enthusiasts and engineers alike.

Ignition to Explosion: How Combustion Fuels Engine Power

The Science of Combustion: How Chemistry Meets Mechanics

The transition from ignition to explosion within a combustion chamber embodies a spectacular convergence of chemistry and mechanics. The basic principles governing combustion can be distilled to the reaction between a fuel — typically hydrocarbons — and oxygen, producing heat, light, and mechanical energy. Once the air-fuel mixture enters the combustion chamber, the presence of an ignition source, such as a spark plug in gasoline engines or the increased pressure in diesel engines, triggers the chemical reaction that sustains combustion. The rate of reaction and energy released are influenced by various factors, including the octane rating of the fuel, which reflects its resistance to knocking, and the ambient temperature and pressure. Additionally, the efficiency of combustion directly correlates with the uniformity of the air-fuel mixture; thus, advanced engine designs often involve stratified charge techniques to enhance the mixing process further. Understanding this intricate interaction between chemistry and mechanics is essential for harnessing the potential of the combustion chamber in energy production and ensuring that engines operate within their optimal parameters.

From Compression to Power Stroke: A Journey Through the Cycle

The cyclical operation of an internal combustion engine can be divided into distinct phases: intake, compression, power, and exhaust. This journey begins when the air-fuel mixture enters the combustion chamber during the intake phase, where the piston’s downward movement creates a vacuum. In the subsequent compression phase, the piston moves upward, compressing the mixture, which increases its temperature and pressure. This compression is vital, as the energy produced during the power stroke relies heavily on the extent of compression applied to the mixture. Upon reaching the necessary threshold, a spark ignites the mixture, leading to a rapid expansion of gases that drives the piston down and generates power. This explosion pushes the crankshaft, which ultimately powers the vehicle through various mechanical linkages. The efficiency of this entire cycle dictates overall engine performance; thus, optimizing each phase is a significant focus of engineering innovations. By fine-tuning factors such as the timing of ignition and improving the design of pistons and connecting rods, engineers can greatly enhance power output and reduce emissions, striking a balance that meets the demands of modern drivers.

Efficiency vs. Power: Striking a Balance in Combustion

In the realm of automotive engineering, a consistent tension exists between power output and fuel efficiency. While every driver desires a powerful engine capable of rapid acceleration and high-speed performance, enhancing power often leads to increased fuel consumption and higher emissions. Here, the combustion chamber’s design and operation steps into the limelight. Engineers employ various strategies to optimize combustion efficiency, including variable valve timing, turbocharging, and advanced fuel injection systems. For instance, direct fuel injection technology allows for precise delivery of fuel directly into the combustion chamber, ensuring more complete combustion, which in turn enhances both power and efficiency. Additionally, improving the thermal efficiency of the combustion process contributes to reducing the overall fuel consumption of an engine. Striking this balance is crucial; manufacturers face pressure to produce engines that not only perform well but also meet increasingly stringent environmental regulations. As such, the evolution of combustion technologies focuses on maximizing fuel efficiency while ensuring adequate power output, representing a significant evolution in automotive engineering.

The Impact of Combustion Chamber Design on Performance and Emissions

Cylinder Head Configurations: Innovations and Implications

The configuration of a cylinder head is a significant determinant of combustion chamber efficiency and overall engine performance. Cylinder heads serve as the interface between the combustion chamber and the rest of the engine’s systems, influencing airflow dynamics, fuel atomization, and the combustion process. Different configurations, such as flat, dome, or wedge-shaped heads, each bring unique advantages and challenges. Innovative designs seek to minimize turbulence and optimize airflow into the combustion chamber, enhancing the efficiency of the air-fuel mixture. Moreover, with the advent of computer-aided design (CAD) technology, engineers can simulate airflow patterns and combustion processes, leading to more refined and effective cylinder head designs. Such innovations help to advance both horsepower output and fuel efficiency, reshaping how performance metrics are achieved while addressing environmental concerns. As manufacturers increasingly prioritize both performance and emissions control, cylinder head configurations will continue to evolve, ensuring that engines remain responsive and clean in the face of modern regulations.

Emissions Control: How Design Choices Can Reduce Your Carbon Footprint

As society progresses towards more sustainable modes of transportation, emissions control has become a paramount focus of combustion chamber design. The combustion process, while effective at generating power, is also a major contributor to greenhouse gases and pollutants. The integration of technologies such as Exhaust Gas Recirculation (EGR), catalytic converters, and particulate filters has maneuvered the industry towards cleaner burning engines. The design of the combustion chamber itself can influence exhaust emissions; engineers are continuously exploring ways to create compact chambers that reduce the residence time of combustion gases, thus minimizing the formation of harmful pollutants. In addition, optimizing the combustion temperatures through advanced cooling mechanisms can significantly reduce nitrogen oxides (NOx) emissions. The increasingly strict global regulations surrounding emissions mean that design choices within the combustion chamber must consider not just performance but also their environmental impact, creating a dual imperative for today’s engineers.

Tuning for Efficiency: Optimizing Combustion for Eco-Friendly Performance

Engine tuning and calibration are vital for achieving optimal efficiency and performance within the combustion chamber. This process involves adjusting various parameters, including ignition timing, fuel injection patterns, and air intake volumes, to ensure that the combustion process is as efficient as possible. Tuning allows engineers to fine-tune the responsiveness of the engine and adapt to various driving conditions, significantly influencing both fuel economy and emissions. The rise of digitization and real-time monitoring systems has made it easier to analyze engine performance data; advanced analytics can predict how adjustments to combustion chamber parameters will impact overall performance metrics. This kind of tuning is particularly critical for high-performance vehicles, where the need for power must be balanced with the need for efficiency. The optimization of the combustion chamber through tuning presents a prime opportunity to improve engine effectiveness while contributing to a more sustainable automotive future.

The Future of Combustion Chambers: Innovations on the Horizon

Alternative Fuels: Adapting Combustion for Tomorrow’s Energy Sources

As the world grapples with the consequences of climate change, the transition to alternative fuels represents a significant paradigm shift in automobile engineering. The combustion chamber is at the forefront of this transformation; it must adapt to new fuel types, such as biofuels, hydrogen, and synthetic fuels. Each of these alternative fuels has distinct combustion characteristics, requiring innovative adjustments in combustion chamber design to maximize efficiency and minimize emissions. Biofuels may require modifications to the fuel delivery systems, while hydrogen engines necessitate high-performance ignition systems capable of handling the unique properties of hydrogen combustion. Furthermore, as electric and hybrid vehicles become more mainstream, the combustion chamber’s design may evolve to facilitate the seamless integration of these technologies, paving the way for advanced hybrid systems that employ both combustion and electrical energy. The ongoing research into optimizing efficiency and reducing emissions is not just a technical challenge; it represents a commitment to a future where engines harmonize with environmental stewardship.

Smart Technology: Integrating Sensors for Real-time Performance Monitoring

The advent of smart technology has revolutionized multiple sectors, and automotive engineering is no exception. The integration of sensors and real-time monitoring systems into the combustion chamber has shed light on optimizing performance and ensuring efficient operation. These sensors can detect parameters such as temperature, pressure, and air-fuel ratios, indispensable for making informed adjustments on the fly. For instance, advanced engine management systems can actively adjust ignition timing and fuel injection based on real-time data, enhancing the combustion process and aligning it with the engine’s operating conditions. Such technology not only improves performance but also paves the way for the development of autonomous systems capable of diagnosing issues and predicting maintenance needs. The continuous advancement of smart technology will undoubtedly reshape the landscape of combustion chamber design and function, leading to vehicles that are safer, more efficient, and environmentally friendly.

New Research Frontiers: What’s Next for Combustion Engine Design?

The quest for improvements in combustion engine design is far from over; ongoing research is continuously uncovering new frontiers in technology and efficiency. Emerging fields such as nanotechnology, for instance, hold the potential to radically alter materials used in combustion chambers, allowing for components that are lighter, stronger, and more heat resistant. Additionally, the exploration of pressure-wave combustion and alternative ignition methods could lead to breakthroughs that enhance energy extraction and reduce emissions further. Research into advanced computational fluid dynamics (CFD) offers insights into intricate interactions within the combustion chamber, paving the way for smarter designs that could yield better performance metrics. As the industry evolves demands and sustainability expectations, researchers, engineers, and manufacturers will need to collaborate closely to push the boundaries of what is possible within combustion chamber technology, ensuring that the engines of tomorrow are not only powerful but also aligned with global sustainability goals.

FAQ

Question: What role does combustion chamber shape play in engine performance? – The shape of the combustion chamber significantly impacts fuel-air mixing, compression ratios, and ultimately engine power output, making its design a crucial factor in overall performance.

Question: How do materials used in combustion chambers affect engine durability? – The choice of materials not only influences weight and heat resistance but also contributes to the engine’s longevity, with modern composites offering enhanced resistance to thermal fatigue and corrosion compared to traditional cast iron.

Question: What is the importance of the air-fuel mixture ratio? – Maintaining the ideal air-fuel mixture ratio (approximately 14.7:1 for gasoline engines) is essential for achieving complete combustion, maximizing energy extraction, and minimizing harmful emissions.

Question: How does engine tuning affect performance? – Engine tuning involves adjusting parameters such as ignition timing and fuel injection to optimize combustion efficiency, balance power output, and improve fuel economy, tailored to different driving conditions.

Question: What innovations in cylinder head designs are being explored? – Engineers are investigating new cylinder head configurations that enhance airflow and mixing, reducing turbulence, which ultimately contributes to improved combustion efficiency and performance metrics.

Question: Why are emissions control technologies necessary in combustion chamber design? – With increasing environmental regulations, emissions control technologies are critical to minimizing pollutants from combustion processes, ensuring that new designs meet stringent standards for sustainability.

Question: How are alternative fuels affecting combustion chamber design? – The rise of alternative fuels like hydrogen and biofuels requires adaptations in combustion chamber design to optimize their distinct combustion properties, improving efficiency and reducing emissions.

Question: What is the future of combustion chambers with the integration of smart technology? – Smart technology enables real-time performance monitoring and adjustments in the combustion process, leading to more efficient and responsive engine designs that enhance performance and simplify maintenance.

Useful Resources

- com

- Khan Academy

- edX

- Coursera

- Udacity

- Massachusetts Institute of Technology (MIT)

- American Society of Automotive Engineers (SAE)

- NASA